Warranty Policy

We will answer all your questions before you buy it, Whatever, we will try to remove all your doubts. Such as, confirm the model, quantity, price, payment method, packaging, brand, etc. One by one before shipment. Then, you will be informed of the logistics method and delivery cycle used.

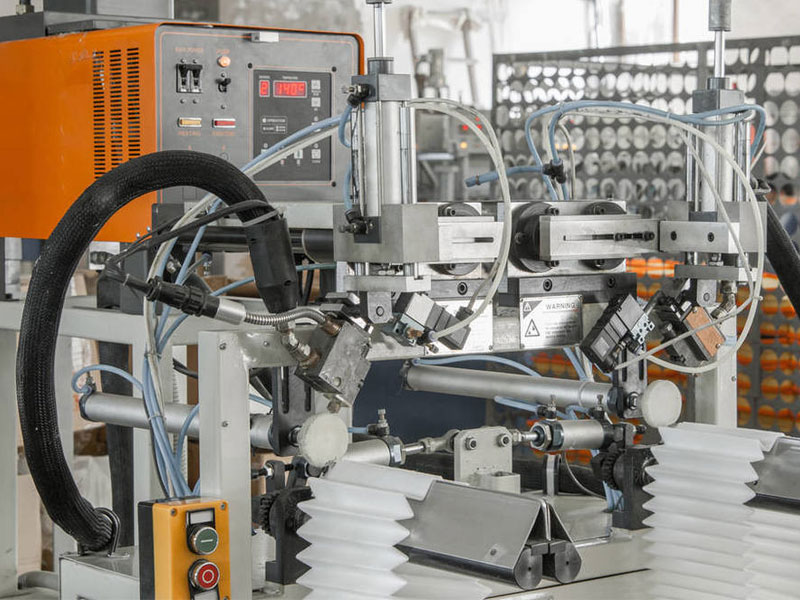

All of our products are manufactured under strict quality control, perfect inspection system and 100% test, which ensure our products have high performance. Basically, we have at least 1 year quality guarantee for our engine parts and chassis parts, but only three to six months for electric products. Because the electric products are easily affected by weather, unprofessional installment, use, wet, etc.

English

English